Does source of sulfur fertilizer matter for alfalfa?

By: Dan Kaiser, Extension nutrient management specialist

December 16, 2021

Earlier this year, I wrote about recent research showing that alfalfa benefits from sulfur fertilizer application. Those studies seem to confirm the current U of M alfalfa fertilizer guidelines for sulfur application, which suggest applying 10 to 25 pounds of sulfur fertilizer per acre, depending on overall production and soil organic matter concentration in the top six inches of soil. But what source of sulfur fertilizer is best for alfalfa? That’s the current focus of two studies funded by Minnesota’s fertilizer check-off dollars through the Agricultural Fertilizer Research and Education Council (AFREC).

Sulfur fertilizer sources

In these two new studies, we compare specific classes of sulfur fertilizer sources at three different rates. One area of interest is whether different elemental sulfur sources can oxidize enough sulfur in a given year. There are two main options for growers if they wish to apply elemental sulfur. The first is elemental sulfur mixed with bentonite, which includes products like Tiger 90. The second option is elemental sulfur that is co-granulated with fertilizer at the manufacturer. This includes products like the MicroEssentials line of phosphate fertilizers and MAP MST (Macronutrient Phosphate + Micronized Sulfur Technology), which is a newer product on the market. The co-granulated sulfur products are touted as being better because they have a lower concentration of sulfur in each granule of fertilizer, which should distribute the product more evenly across the field. So, one of the big questions is whether these new products have an advantage over other sulfur fertilizer sources.

One of the two new studies was established in spring 2020 in Rosemount on a deep loess soil. The study features multiple rates of sulfur (0, 10, 20, and 30 lbs S/ac) applied annually to the same plots. Initial application of sulfur fertilizer was made spring 2020 and an additional application is made after the first cutting for each year of the study. The two sources of sulfur are potassium sulfate and potash-MST.

I have received some criticism in the past when using potassium-based products as they are not widely available. However, the release of sulfate from potassium sulfate is similar to ammonium sulfate (AMS), which is more commonly used. We use potash-MST because nearly all of the sulfur in this product is elemental sulfur, which differs from MicroEssentials, which is half elemental sulfur and half AMS. Phosphate fertilizer sources, such as MAP or DAP, also contain sulfur impurities as sulfate, which are not accounted for in the guaranteed analysis and could impact our results. It is important to limit some of these unknowns so that we can get clear results on the availability of elemental sulfur.

Rosemount study results

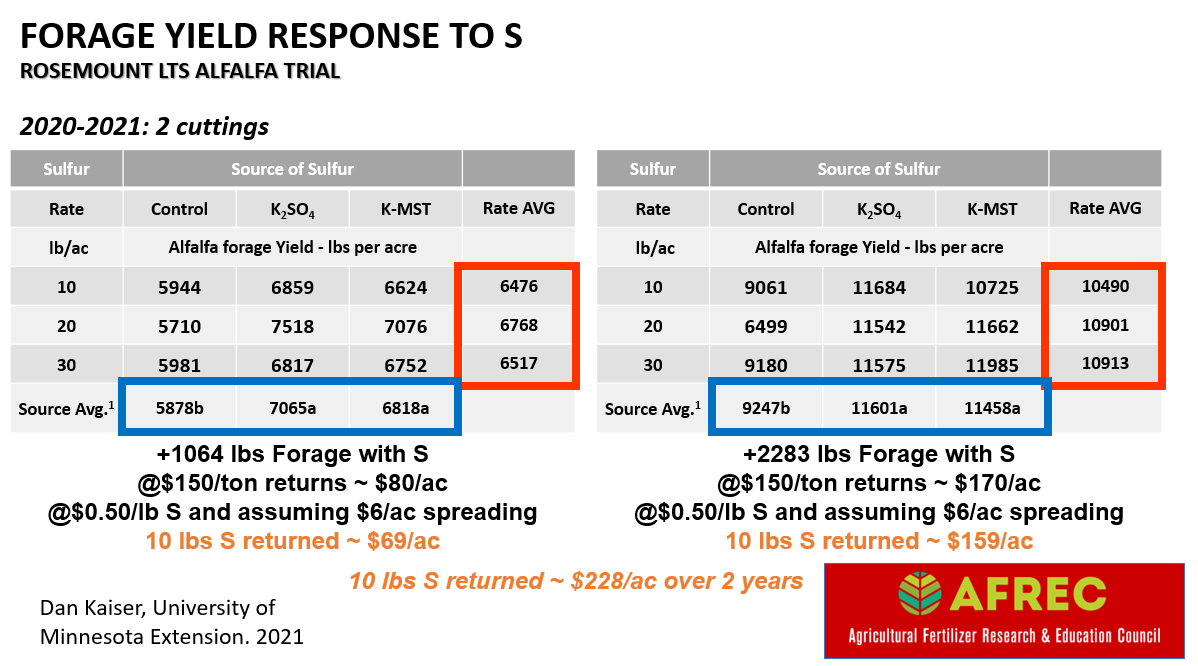

Only two cuttings were taken after the initial 2020 fertilizer application and before the next fertilizer application in 2021. In that time, there was a significant increase in forage yield when 10 pounds S/ac was applied, averaging a little over 1,000 pounds dry weight over the two cutting regardless of sulfur source. Similar results were found for the remaining three cuttings taken in 2021, but the yield increase due to sulfur was close to 2,300 pounds dry weight for cuts two through four in 2021. Again, there was no evidence that more than 10 pounds of sulfur was required.

Discounting quality and assuming a forage value of $150 per ton and a sulfur cost of $0.50 per pound, the total return from sulfur fertilizer application at the Rosemount site was close to $230 per acre. Even if you double the price of the sulfur fertilizer, there would still be a significant economic return from sulfur application.

How long does sulfur stay in the soil profile?

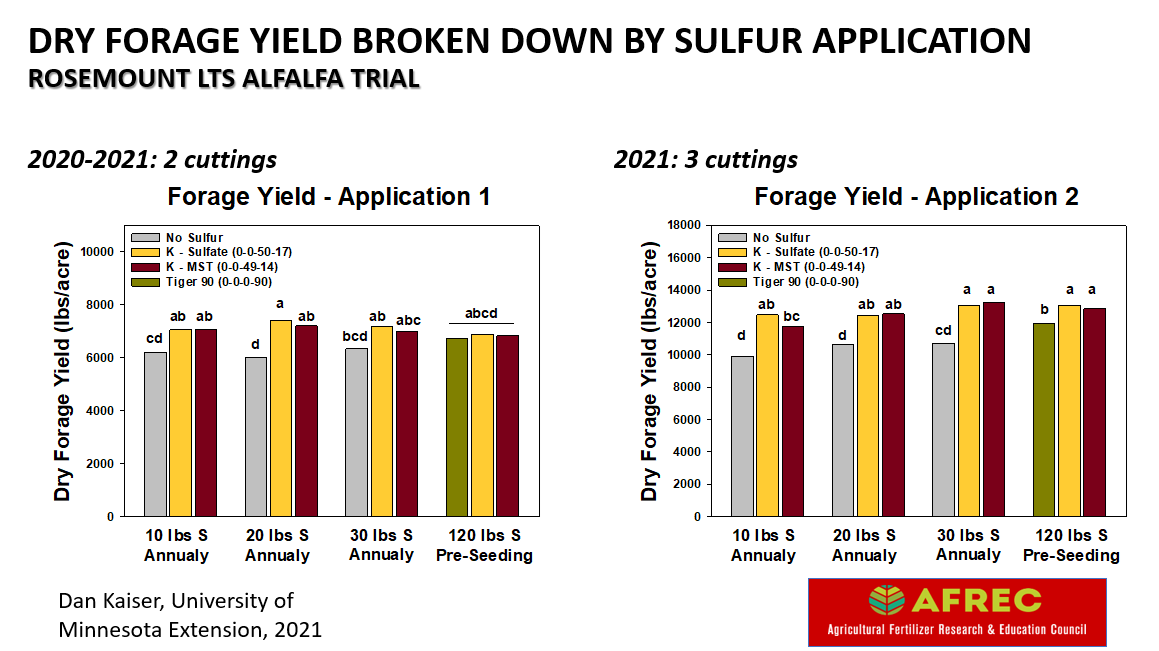

One other area I am studying is how long sulfur sticks around in the soil profile. When the sites were established, 120 pounds of sulfur was applied as potassium sulfate, potash MST, and Tiger 90. Annual applications will not be made on these plots over time so that we can see how long sulfate stays in the soil profile and how higher rates of elemental sulfur oxidize over time. Initial results indicate that the higher rates yielded slightly less for the initial two cuttings. However, the K sulfate and K-MST sulfur sources yielded similar to the maximum yield achieved at the site. Tiger 90 yielded less when applied at 120 pounds than the 10 pounds annual rate, but it did increase yield over the control. When incorporated before seeding, the material does oxidize, but the potential for oxidation seems to be less than the MST products, which also contains elemental sulfur.

What does this mean for alfalfa producers?

This data indicates that application of as little as 10 pounds of sulfur per acre can be highly profitable for alfalfa production and that there is some flexibility in the sulfur fertilizer source growers use. A second site has been established in Morris to study the impacts of sulfur on higher organic matter soils. We will see if the 10-pound rate is sufficient over time or whether differences will be found as the stand ages, warranting higher rates of fertilizer. The data also confirms other results showing less availability of the sulfur and bentonite mixture (in this case, Tiger 90). I have new research looking at surface application of Tiger 90 in the fall without incorporation to see if that provides a better opportunity for the elemental sulfur in the material to oxidize to available sulfate. Since the sulfur plus bentonite products are sold, we need to research whether management should be altered to ensure that these products have the best chance to supply sulfur to crops that need it.

This article was originally published in the Minnesota Crop News. Republished here with permission.